What is Machine Vision?

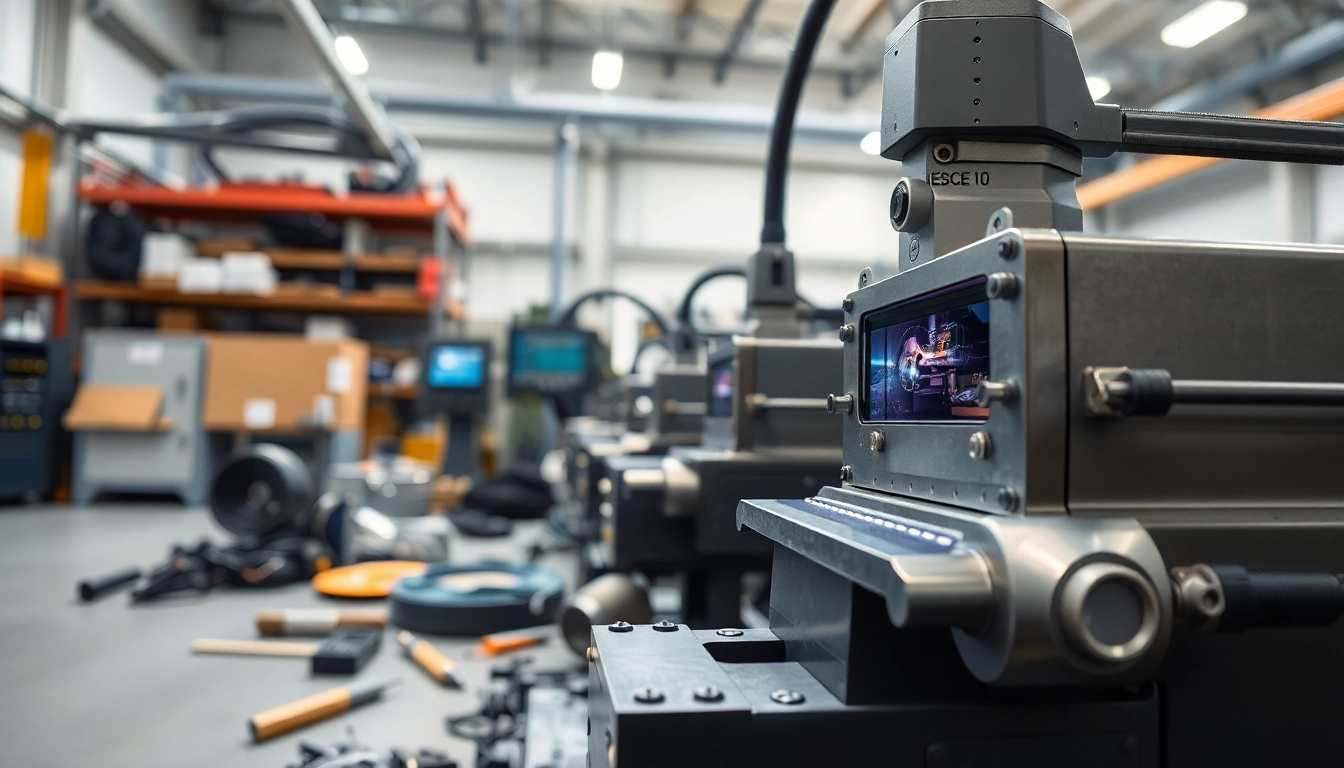

Machine vision refers to the technology and methods that allow machines to interpret and act upon visual information. This technology finds extensive applications across various industries, notably in manufacturing, where it is utilized for quality control, assembly guidance, and more. The integration of machine vision enables automation systems to analyze images from cameras, process the visual data with software, and make decisions, which fundamentally assists in enhancing efficiency and effectiveness in industrial processes.

Defining Machine Vision Technology

At its core, machine vision encompasses a series of technologies that mimic human vision to perform automated tasks. This typically involves the use of cameras, sensors, and intelligent software that collectively enable machines to “see.” The primary objective is to enhance the capabilities of machines to perform tasks requiring visual recognition, which can significantly reduce the need for human intervention.

The Role of Imaging in Automation

Imaging plays a critical role in automation, particularly in manufacturing settings where precision and quality control are paramount. Machine vision systems utilize various imaging techniques, including 2D and 3D imaging, to capture real-time data about the products being manufactured. For instance, cameras can capture high-resolution images of products moving along a production line, and sophisticated algorithms analyze these images to detect defects or deviations from quality standards.

Core Components of Machine Vision Systems

A machine vision system comprises several essential components:

- Cameras: These capture visual information. Depending on the application, different types of cameras (e.g., CCD, CMOS) may be employed.

- Lighting: Proper illumination is crucial for ensuring image quality and contrast.

- Processing Unit: This is where the captured data is processed. It usually involves specialized software and sometimes hardware accelerators.

- Software Algorithms: These algorithms analyze the images to identify patterns, defects, or other relevant information.

- Output Interface: This communicates the results to the connected systems or operators, facilitating rapid decision-making.

Applications of Machine Vision

Machine vision finds diverse applications across multiple sectors due to its versatility and efficiency. Its primary applications include:

Quality Control and Inspection

One of the most significant applications of machine vision is in quality control and inspection. By systematically inspecting products for defects or inconsistencies, companies can maintain high-quality standards. Machine vision systems can examine products at speeds far surpassing human inspection capabilities, allowing for rapid feedback and correction in manufacturing processes.

Guiding Assembly Processes

Machine vision systems can provide real-time feedback during assembly processes. They can guide robotic arms or other automated equipment by detecting the position and orientation of components, ensuring that assembly is performed accurately. This capability minimizes errors and reduces the likelihood of rework, thereby enhancing overall production efficiency.

Barcode and Label Reading

Machine vision is widely used for reading barcodes and labels in various industries, from logistics and inventory management to packaging. These systems employ image recognition capabilities to scan and interpret barcodes quickly, facilitating automated tracking and inventory control, which are critical in supply chain management.

Benefits of Implementing Machine Vision

Integrating machine vision technology into operations offers numerous benefits:

Enhancing Efficiency and Accuracy

Machine vision significantly enhances efficiency by replacing manual inspection processes, which can be slow and error-prone. Automated systems can operate continuously without fatigue, ensuring that high accuracy levels are maintained. This leads to more consistent product quality and reduced waste—ultimately improving the hour-by-hour yield and profitability of manufacturing operations.

Reducing Operational Costs

While the initial investment in machine vision technology may seem substantial, the long-term cost savings prove significant. By reducing manpower requirements and minimizing defects, organizations experience lower operational costs. Additionally, machine vision can reduce the frequency of product recalls and returns, further contributing to cost efficiency.

Improving Data Collection and Analysis

Machine vision systems facilitate better data collection and analysis by systematically gathering visual data throughout the production process. This data can help in identifying trends, predicting maintenance needs, and optimizing processes. It enables organizations to implement continuous improvement initiatives based on accurate information rather than assumptions.

Challenges in Machine Vision

Despite its advantages, implementing machine vision can present certain challenges:

Integration with Existing Systems

Integrating machine vision systems with existing equipment and workflows can be complex. Organizations may encounter compatibility issues and require significant changes to their production layouts. To address this, stakeholders should engage in thorough planning and testing phases to ensure smooth integration, often utilizing pilot programs before full implementation.

Choosing the Right Technology

The market offers a vast array of machine vision technologies, which can make selecting the appropriate one challenging. Factors to consider include application requirements, environmental conditions, and budget constraints. Consulting with domain experts or leveraging vendor knowledge can provide valuable insights into selecting the best-fit systems for specific applications.

Maintenance and Upkeep of Vision Systems

Machine vision systems require regular maintenance and calibration to ensure accurate performance. This includes cleaning cameras, checking software updates, and ensuring that lighting conditions remain optimal. Creating a preventative maintenance plan can mitigate downtime and maintain efficiency within the operational processes.

Future Trends in Machine Vision

The future of machine vision looks promising, with several trends shaping its evolution:

Advancements in AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) is revolutionizing machine vision capabilities. These technologies allow systems to learn from data and adapt over time, improving their accuracy and decision-making abilities. For instance, systems can be trained to recognize new defects based on historical data, continuously enhancing reliability and performance.

More Accessible Machine Vision Solutions

As technology progresses, machine vision solutions are becoming more accessible to smaller businesses. With the advent of lower-cost cameras and processing technologies, even small manufacturers can implement sophisticated machine vision systems without prohibitive startup costs. This democratization of technology is expected to spur widespread adoption across industries.

Expanding Uses Across Industries

While manufacturing remains the primary industry utilizing machine vision, its applications are increasingly expanding into areas such as agriculture, healthcare, and autonomous vehicles. For example, machine vision systems can be applied in precise crop monitoring and in diagnostic tools within healthcare, highlighting the versatility of this technology.